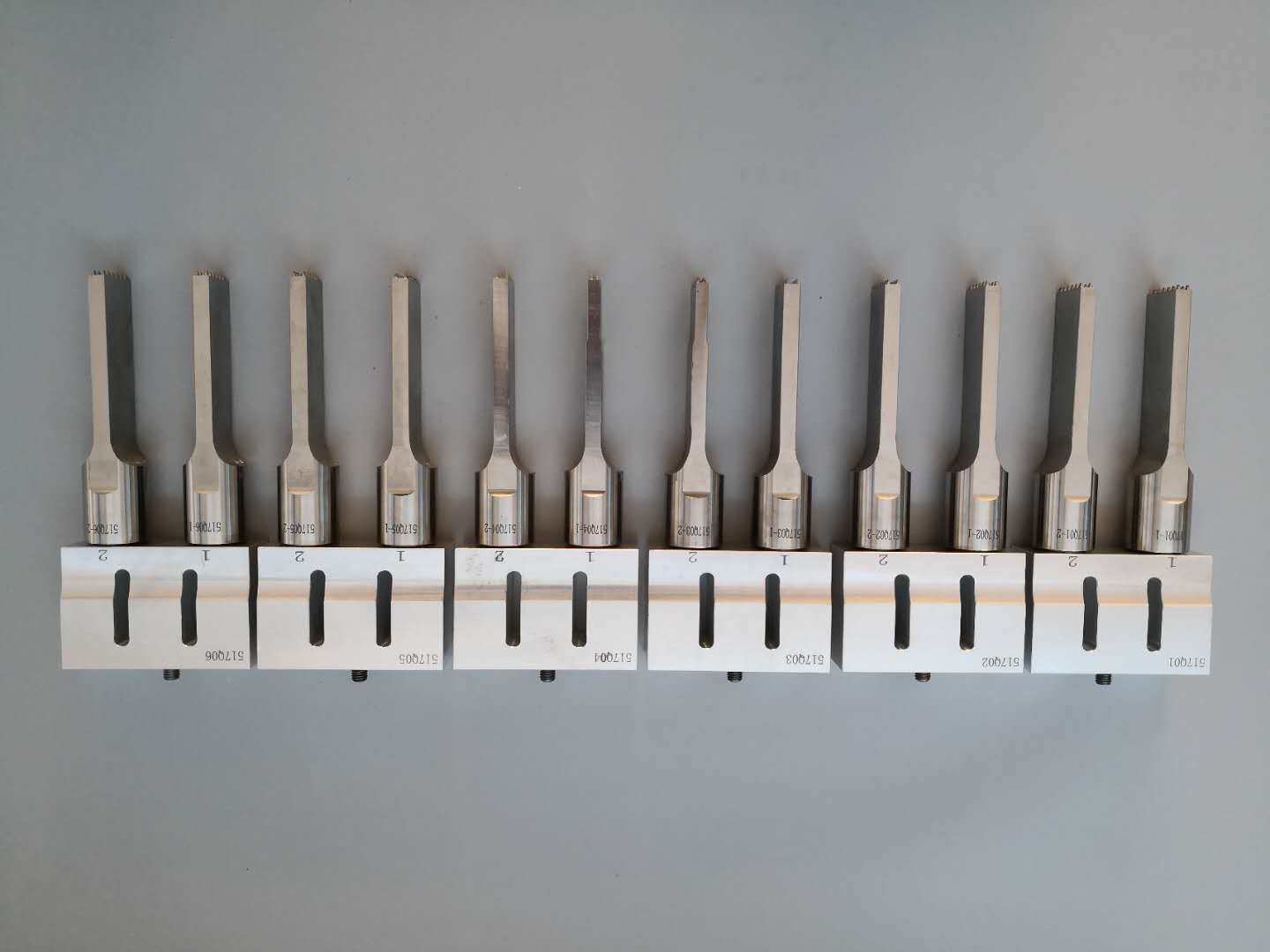

35K mother-and-son welding head

Ultrasonic 35K titanium alloy welding head

-Ultrasonic welding machine has a center frequency, such as 20KHz, 40 KHz and so on

-The working frequency of the welding machine is mainly determined by the frequency of the transducer, the transformer, and the mechanical resonance of the welding head

-The generator frequency is adjusted according to the mechanical resonance frequency, so that the welding head works in a resonant state. Each part is designed as a resonant body of one half wavelength

-Generator and mechanical resonance frequency have a resonant operating range, generally set at 0.5 KHz

- Details

- Parameter

1、The amplitude parameter of the die

Amplitude is a key parameter for materials that need to be welded, which is equivalent to the temperature of ferrochrome. If the temperature is not reached, the welding will not be able to be connected. If the temperature is too high, the raw materials will be burnt or the structure will be damaged and the strength will be poor. Because each company chooses a different transducer, the amplitude of the transducer's output varies

2、Die frequency parameter

Any company has a center frequency ultrasonic welding machine, such as 20 KHz, 40 KHz, the work frequency of the welding machine is mainly composed of Transducer (Transducer), amplitude (Booster), and the welding head (Horn) of mechanical resonance frequency, the frequency of the generator according to the mechanical resonance frequency adjustment, in order to achieve consistent, make the welding head work in resonant state, every part of the design into one and a half wavelength resonance body

3、Vibration joint spot welding head, variable amplitude rod

Both are designed as a half-wavelength resonant body with a working frequency. In the working state, the amplitude of the two ends is the maximum and the stress is the minimum, while the node corresponding to the middle position is zero and the stress is the maximum. General design for fixed node position, but usually the fixed position of the design thickness is greater than 3 mm, or groove is fixed, so the fixed position is not must be zero amplitude, this will lead to some calls, and part of the energy loss, the sound isolation usually with a rubber ring with other parts, or block with sound insulation materials, and energy loss be considered in the design of amplitude parameters.

The characteristics of various materials of ultrasonic mold are as follows

1、Aluminum magnesium alloy (7075-t651, 2024-t651, 6061-t651)

2、6061T651: used in low output HORN manufacturing, bremsstrahlung good, soft quality

3、Titanium alloy: used for continuous vibration machine, bremsstrahlung high, good heat conduction, high hardness, and high cost

4、Domestic hard aluminum alloy: domestic material, used for ordinary aluminum processing, low heat conduction, high ultrasonic mechanical loss, low cost